Alumina balls / ceramic balls / grinding media / mill grinding balls

Alumina grinding balls with raw materials calcined alumina is mainly applied in wet grinding mill of glaze milling , tile body milling etc. Wet ball mill smashes materials mainly through grinding instead of impacting, so good proportion of using ceramic balls is required to calculate exactly ,Chemshun Ceramics have great capabilities of calculating 92% 95% Al2O3 grinding balls proportion quantity , size according to customer's offered information including : granularity of raw materials , diameter and rotary speed of ball mill . too many alumina balls filled in the ball mill will bring mill bricks abrasion damage more quickly .

alumina ceramic cylinder characters

-- High hardness with Moh's hardness 9 grade

-- High abrasion and Lower abrasion loss

-- Widely application for grinding materials

-- High density with stronger impact resistance

-- Chemical resistance for acidic medium application

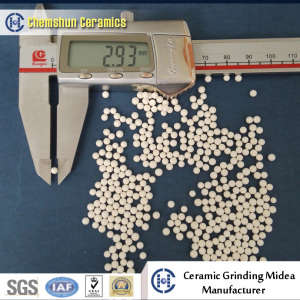

chumshun grinding ball size

Application industry :

Alumina grinding balls with raw materials calcined alumina is mainly applied in wet grinding mill of glaze milling , tile body milling etc. Wet ball mill smashes materials mainly through grinding instead of impacting, so good proportion of using ceramic balls is required to calculate exactly ,Chemshun Ceramics have great capabilities of calculating 92% 95% Al2O3 grinding balls proportion quantity , size according to customer's offered information including : granularity of raw materials , diameter and rotary speed of ball mill . too many alumina balls filled in the ball mill will bring mill bricks abrasion damage more quickly .

alumina ceramic cylinder characters

-- High hardness with Moh's hardness 9 grade

-- High abrasion and Lower abrasion loss

-- Widely application for grinding materials

-- High density with stronger impact resistance

-- Chemical resistance for acidic medium application

chumshun grinding ball size

| Size (mm) | D1-3 | D6/8/10/13/16/20/25 | D30/40 | D50/60 |

| Tolerance (±mm) | 0.5 | 1 | 2 | 3 |

Application industry :

- mining industry Cement industry Chemical industry Ceramics industry paint industry,

| Item | Chemshun95® | Chemshun92® |

| Alumina Content(%) | ≥95 | ≥92 |

| Density (g/cm3) | ≥3.68 | ≥3.6 |

| Moh's Hardness (Mohs) | 9 | 9 |

| Water Absorption (%) | ≤0.01 | ≤0.01 |

| Self-wear Loss | 0.06‰ | <0.01% |